Subsea Pipeline Tie-In

Wednesday, February 17, 2016Subsea tie-in is typically made by diver-assisted flange connectors for shallow water pipelines and diverless remotely operated vehicle (ROV) connectors for deepwater pipelines.

There are three types of

connectors available: flange, clamp (Graylok type), and collet connectors.

Clamp or collet connector is more favorable over the flange connector due to

ROV operability, offshore connection time, and available tie-in tools from

contractors.

The methods of pipeline tie-in

are explained below:

Spoolpiece

Divers measure and then assist

the installation of a piece of pipe to fit in between the two ends of flowline

to be tied together. Misalignment of the two pipes can be accommodated by

installing bends into the spool, and inaccuracies in placing the pipelines down

can be accommodated when the spool is made up (after diver measurements).

The connection method can either

be by flanges or welding. The welding method requires a hyperbaric habitat.

From a design viewpoint, should there be large flowline expansion, then this

can also be accommodated by incorporating a dogleg in the spool. This will

permit expansion of the pipe without transmitting high loads into the adjacent

pipe.

Lateral Pull

Lateral deflection involves

positioning the flowline end to one side of the target structure and then

pulling it laterally into position. The

flowline may be pulled towards the target by a single wire, or a series of

wires may be developed through dead-man anchors to give greater control of

alignment. A bell mouth or stab-in guides usually assist final alignment.

For large diameters such as

export lines or bundles, it is necessary to make a length of pipeline neutrally

buoyant. This gives greater flexibility and reduces the pull forces, but can

expose the pipe to large current forces.

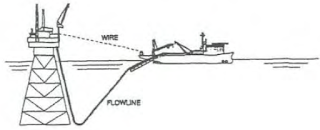

J-tube Pull-in

This method requires the flowline

to have the capacity to easily move axially over a relatively large distance.

This limits the option to pulling the flowline directly from the pipelay

vessel. The method of J-tube pull-in is to connect the flowline to a wire and,

by pulling the wire, to pull the flowline through a riser (J-tube) up to the

topsides of the platform. This method requires the J-tube to be of a reasonably

large diameter compared to the flowline.

Connect and Lay Away

This method is very similar to

the J-tube pull-in method with the exception that the tie-in is performed

subsea. This method is usually applied in diverless operations, where a

mechanical connecting system will be utilized to perform the connection. This

system is mainly used at subsea manifolds/wellheads, where the water depth

prohibits the use of divers. This is the only system developed for performing

diverless connection of pipelines.

Stalk-on

The stalk-on method is primarily

used in shallow water applications (less than 40 m) and hence would only be

applicable in the Southern North Sea. The method involves laying the flowline

down adjacent to the jacket it shall be tied into. The vessel maneuvers over

the flowline, lifts it up and welds on (or flanges on) the jacket riser. The

pipeline and riser are then lowered onto the seabed/jacket. The jacket clamps

are subsequently closed around the riser.

--

Source:

Lee, Jaeyoung. Introduction to Offshore Pipelines and Risers. 2007.

Bai, Yong and Bai, Qiang. Subsea Pipelines And Risers. USA: Elsevier Inc. 2005.

0 komentar