Pipeline Pigging

Wednesday, February 17, 2016Pig is a device used for cleaning a pipeline or separating fluids being moved down the pipeline. It is inserted in the pipeline and carried along by pressurized flow of water, oil, or gas. An intelligent pig is fitted with magnetic or ultrasonic sensors to detect corrosion or defects in the pipeline. Pigging is performed during installation and operation for such purposes as:

During Installation

- Debris removing, cleaning, and gauging

- Watering, dewatering, and drying

- Commissioning

- During Operation

Cleaning – wax/scale/condensate buildups removal

- Inventory management – sweeping out batching products

- Corrosion and scale control

- Inspection – geometry (physical damage), corrosion, crack, leak detection

Miscellaneous

- Decommissioning

- Isolation

- Recommissioning

Pigging Procedure

- Pressure and Flow Rate

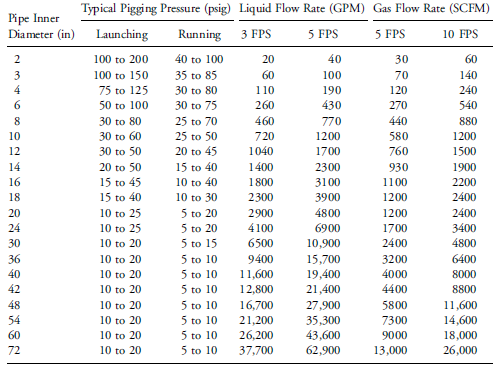

Operating pigging pressures and

fluid flow rates should be carefully controlled. Velocity of driving fluid is

usually between 3 feet per second and 5 feet per second during pigging.

Recommended ranges of operating pressures and flow rates are presented in table

below:

- Pre-Run Inspection

If the pig has been run before,

it should be inspected to assure that it will run again without stopping in the

pipeline. Measure the outside diameter of the pig’s sealing surface. This

diameter must be larger than the inside pipe diameter to maintain a good seal.

Inspect the sealing surfaces to assure there are no cuts, tears, punctures, or

other damage that will affect the pig’s ability to run in the pipeline. The unrestrained

diameter of brush pigs should also be measured to assure that the brushes will

maintain contact with the pipe wall during the complete run. When using

brush-type mandrel cleaning pigs, the brushes should be inspected for corrosion

or breakage. Every precaution should be taken to prevent these brushes from

breaking in the pipeline. Loose bristles can damage valves, instrumentation,

and other pipeline equipment. All components of brush-type mandrel pigs should

be checked to be certain that they are tight and in good condition.

- Freeing a Stuck Pig

Getting the pig stuck rarely

happens in pipeline that is pigged routinely, but can happen when pigging a

pipeline that has been neglected or never pigged before. If a pig becomes

stuck, it is important to identify the cause. Retrieving the pig is the first

priority. When bidirectional pigs are used, stuck pigs may be recovered with

reverse flow.

Pig tracking is normally done on

critical projects and when attempting to locate stuck pigs. A pig tracking system

consists of a transmitter mounted on the pig, an antenna, and a receiver that

records and stores each pig passage. In addition, the operator can see and hear

the signal of the pig passing under the antenna. The antenna and receiver are

simply laid on the ground above and in line with the pipe and the passage of

the pig is heard, seen, and recorded.

Sometimes a pig without a

transmitter fails to come into the receiver because it gets stuck somewhere in

the line. When this happens, the pig cups usually flip forward and flow

continues around the stuck pig. In order to find the stuck pig, another pig

with a transmitter is launched and tracked closely at all points that are

readily accessible. When the transmitter pig passes one tracking point but

never reaches the next point, it is assumed the transmitter pig has reached the

stuck pig and they are both stuck. The line is then walked, carrying the

antenna and receiver until the transmitter pig is pinpointed. Both pigs and the

debris ahead of the pigs is then removed by cutting the pipe behind and well

ahead of the stuck pig.

In addition, to know more about

how pipeline pigging work, you can watch the video below:

There’s one more thing we should

know about pipeline pigging. It’s pig launcher/pig trap. I will explain about

it in other article soon.

--

Source:

Lee, Jaeyoung. Introduction to Offshore Pipelines and Risers. 2007.

Guo, Boyun, Shanhong Song, Jacob Chacko, Ali Ghalambor. USA. 2005.

0 komentar