Pipeline Construction

Wednesday, February 17, 2016- Hot Rolling

- Cold Rolling

- Hot Tube Fiercing

- Welded Pipe

Hot Rolling

Hot rolling is a method to build

semi-finished product of pipeline. The steel is formed to become flat product

which is used to built a tube/pipeline later on. This method use hot stell and

a roller on top and bottom of it and turn the hot steel become thinner and

thinner until meet the desired thickness.

Cold Rolling

This method is used to turn flat

product from the previous method, into sheet steel. This method takes a few

times of cold rolling until the flat product become sheet steel. The next step

is heating/annealing the sheet steel to make it softer and terminated with

temper rolling to “ironing” the steel.

Hot Tube Piercing

Hot tube piercing is a method to

build the seamless pipeline. The first step is heating the steel and then a

pierce is pierced into the hot steel.The pierce will make a long hole inside

the steel. To make the outside diameter and wall thickness, this method is

followed with hot tube rolling. It will reduce the wall thickness without

reducing the outside diameter.

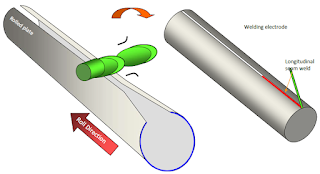

Welded Pipe

This method is used to make a

pipeline with big outside diameter. It use material from the previous method which

is sheet steel from hot rolling. After that, the sheet steel is formed into

tube and sealed bby welding. Due to it’s way of welding, this method is divided

into two:

- Longitudinal Welded Pipe

- Spiral Welded Pipe

--

Source:

Slide presentation of

Construction Material for Marine Environment lecture. Ocean Engineering, ITB.

2013.

0 komentar