Pipeline Thermal Insulation

Wednesday, February 17, 2016To keep the conveyed fluid warm, the pipeline should be heated by active or passive methods. The active heating methods include, electric heat tracing wires wrapped around the pipeline, circulating hot water through the annulus of pipe-in-pipe, etc. The passive heating method is insulation coating, burial, covering, etc.

Oilfield pipelines are insulated

mainly to conserve heat. The need to keep the product in the pipeline at a

temperature higher than the ambient could exist for the following reasons including:

- Preventing formation of gas hydrates

- Preventing formation of wax or asphaltenes

- Enhancing product flow properties

- Increasing cool-down time after shutting down

- Meeting other operational/process equipment requirements

In liquefied gas pipelines, such

as LNG, insulation is required to maintain the cold temperature of the gas to

keep it in a liquid state. This chapter describes commonly used insulation

materials, insulation finish on pipes, and general requirements for insulation

of offshore and deepwater pipeline.

Insulation Material

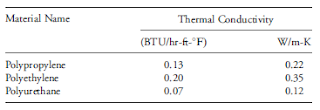

Polypropylene, polyethylene, and

polyurethane are three base materials widely used in the industry for pipeline

insulation. Their thermal conductivities are given in table below:

Depending on applications, these

base materials are used in different forms resulting in different overall

conductivities. A 3-layer polypropylene applied to pipe surface has a conductivity

of 0.13 BTU/hr-ft-8F, while a 4-layer polypropylene has a conductivity of 0.10

BTU/hr-ft-8F. Solid polypropylene has higher conductivity than polypropylene foam.

Polymer syntactic polyurethane has a conductivity of 0.07 BTU/hr-ft-8F, while

glass syntactic polyurethane has a conductivity of 0.09 BTU/hr-ft-8F. These materials

have lower conductivities in dry conditions such as that in pipe-in-pipe applications.

Because of its low thermal

conductivity, more and more polyurethane foams are used in deepwater

applications. Physical properties of polyurethane foams include density, compressive

strength, thermal conductivity, closed cell content, leachable halides,

flammability, tensile strength, tensile modulus, and water absorption. The

values of these properties vary depending on density of the foam.

--

Source:

Lee, Jaeyoung. Introduction to

Offshore Pipelines and Risers. 2007.

Guo, Boyun, Shanhong Song, Jacob

Chacko, Ali Ghalambor. USA. 2005.

0 komentar